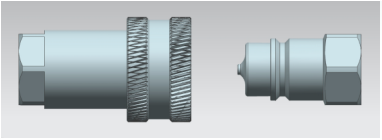

Quick release couplings solve the problem of quick connection and disconnection of flexible hose assemblies. The connection can be made faster and easier than in the case of standard screwed couplings (threaded, flanged) because it is made by hand, with no tools. Usually, it requires only pushing a plug into a socket. Locking occurs automatically, using the spring mechanism. The most often the plug is blocked in the socket with steel balls. In many cases connection and disconnection can be made with one hand only ("one hand operation"). The use of quick release couplings facilities assembly. It enables fast and easy replacement of interchangeable modules of hydraulic systems, saving time and money. Construction - basic elements (illustrated by the example of ISO-B quick release double shut-off coupling)

TYPE - DC DOUBLE CHECK VALVE (DOUBLE SHUT OFF) QUICK RELEASE COUPLINGS

TYPE-DC COUPLERS ARE HAVING BUILT IN SELF SEALING VALVES ON PLUG & SOCKET ENDS SUCH THAT BOTH SOCKET AND PLUGS ARE SEALED INSTANTLY ON DISCONNECTION.

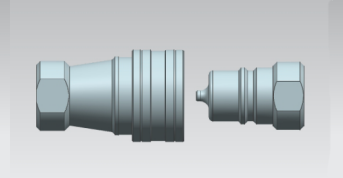

WHEN PLUG AND SOCKET ARE SEPERATED

The valve of the socket and plug is pushed against the

valve seat and closed automatically. There is no leakage

of the fluid

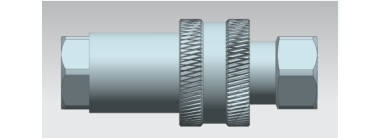

WHEN PLUG AND SOCKET ARE CONNECTED

The valves of the socket and plug are pushed against each other, the interior of the coupling is opened and the fluid flows. The O-ring inside the socket is forced against the outside of the plug and there is no leakage to the outside.

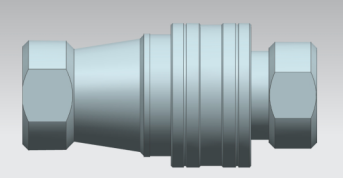

Features

Since both the plug and socket have a value, there is no leakage of gas, oil etc. from either the socket or plug ends when disconnected. Since they are manufactured by an especially high precision machining process, air tightness is a high 10* mmHgl/sec. The hose dose not twist. Designed for use in a wide range of applications

| QRC SIZE A* | B | C | D | E | F | G | H | I | J | Working Pressure (bar) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1/4" | 50 | 33 | 19 | 27 | 36 | 11 | 25 | 11.8 | 19A/F | 350 |

| 3/8" | 55 | 35 | 20 | 32 | 36.5 | 11 | 25.5 | 17.2 | 22A/F | 300 |

| 1/2" | 67.5 | 42.5 | 25 | 40.5 | 45 | 13 | 32 | 20.5 | 27A/F | 250 |

| 3/4" | 80.5 | 52.5 | 28 | 47 | 57 | 16.5 | 40.5 | 29.1 | 35A/F | 250 |

| 1" | 94 | 66.8 | 27.2 | 57 | 59.5 | 16 | 43.5 | 34.3 | 41A/F | 230 |

| 1 1/4" | 117.5 | 77 | 40.5 | 70.5 | 75 | 23 | 52 | 45 | 50A/F | 230 |

| 1 1/2" | 133 | 85 | 48 | 84.5 | 84 | 22.5 | 61.5 | 55 | 60A/F | 190 |

The valve of the socket and plug is pushed against the valve seat and closed automatically.

There is no leakage of the fluid.

The valves of the socket and plug are pushed against each other, the interior of the coupling is opened, and the outside of the plug and there is no leakage to the outside.

Features

| QRC SIZE A* | B | C | D | E | F | G | H | I | J | K | L | Working Pressure (bar) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8" | 16.0 | 20.0 | 43.0 | 35.8 | 7.5 | 14.0 | 10.9 | 30.0 | 14.2 | 15.8 | 14.0A/F | 250 |

| 1/4" | 22.0 | 28.0 | 58.0 | 48.0 | 11.0 | 18.0 | 14.0 | 36.0 | 13.0 | 23.0 | 19.0A/F | 250 |

| 3/8" | 26.0 | 35.0 | 65.0 | 52.0 | 14.0 | 20.0 | 19.1 | 40.0 | 14.0 | 26.0 | 22.0A/F | 250 |

| 1/2" | 32.0 | 42.0 | 71.0 | 56.0 | 15.0 | 24.0 | 23.5 | 45.0 | 19.0 | 26.0 | 28.0A/F | 250 |

| 3/4" | 36.0 | 45.0 | 76.0 | 58.0 | 18.0 | 26.0 | 31.4 | 49.0 | 20.0 | 29.0 | 32.0A/F | 160 |

| 1" | 45.0 | 55.0 | 45.0 | 85.0 | 63.0 | 22.0 | 37.7 | 41.0 | 56.0 | 26.0 | 30.0A/F | 100 |

| 1 1/4" | 58.0 | 70.0 | 95.0 | 72.0 | 23.0 | 29.0 | 41.9 | 59.0 | 24.0 | 35.0 | 51.0A/F | 63 |

| 1 1/2" | 64.0 | 75.0 | 95.0 | 72.0 | 23.0 | 29.0 | 44.9 | 59.0 | 24.0 | 35.0 | 55.0A/F | 63 |